Mapping Glycol Heat Pipes with GPR at YYC Airport

Concrete Scanning

CLIENT

YYC Calgary Airport Authority

TIME

1-2 days

SERVICE

Concrete Scanning

The Challenge

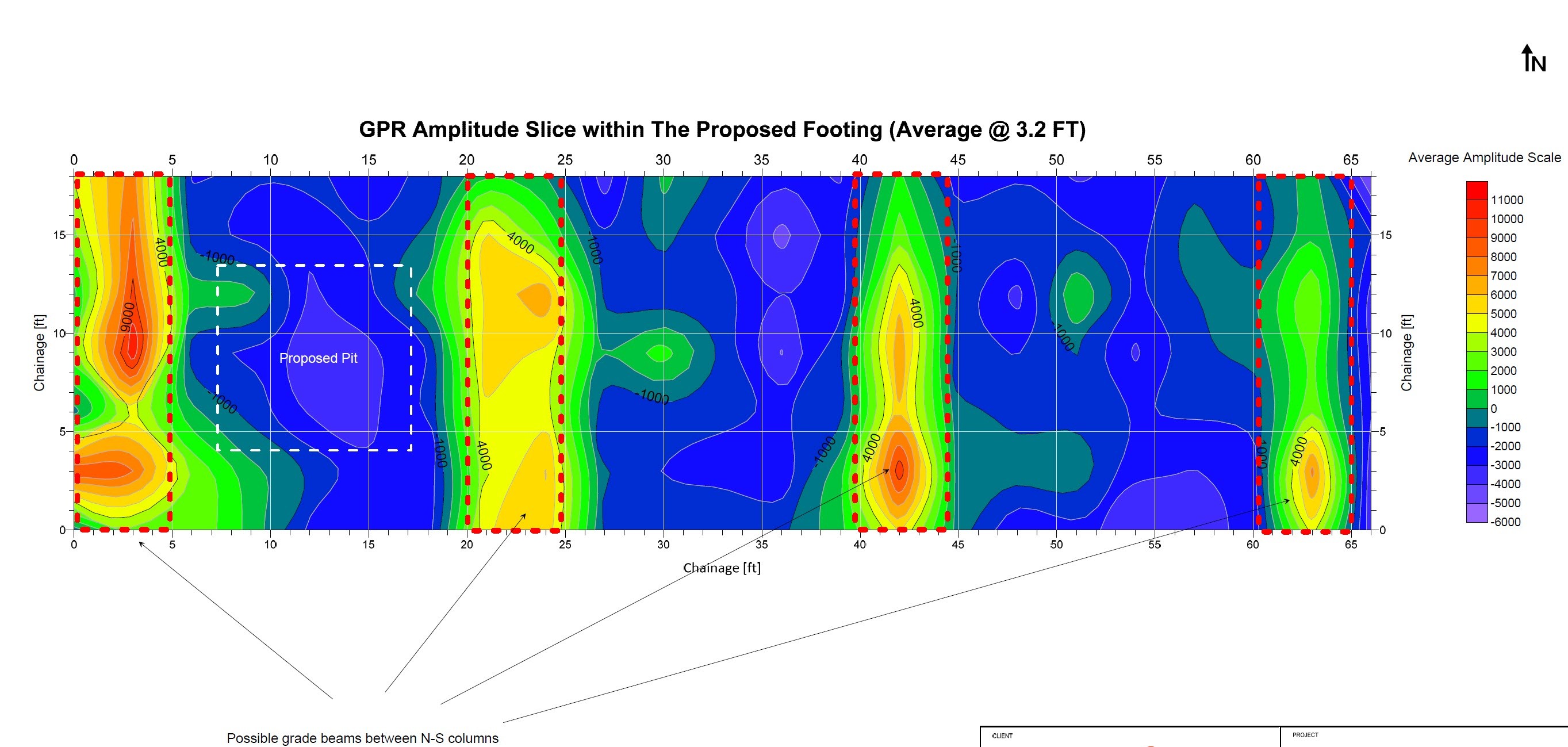

Airport floor slabs contained dense reinforcement, multiple layers of electrical conduits, and an extensive glycol heat pipe network used for temperature control. Existing documentation was limited, and access was restricted in many areas. Any accidental strike during coring or anchor installation could have resulted in system shutdowns, safety hazards, costly repairs, and operational delays. Conventional scanning methods were challenged by congestion and tight working spaces.

The Solution

Scantec deployed high-frequency GPR systems with compact palm antennas, allowing access to tight areas while achieving exceptional resolution in heavily reinforced concrete. The survey successfully identified and differentiated glycol heat pipes, electrical conduits, and reinforcing steel within the slabs.

To improve clarity and confidence, Scantec applied advanced 3D data reconstruction and visualization techniques, transforming individual scan lines into clear three-dimensional models of the heat pipe patterns. Detected features were interpreted and marked in real time, enabling construction teams to safely adjust coring locations and anchor layouts.

The Outcome

The integrated GPR approach delivered:

Accurate mapping of glycol heat pipe networks within congested slabs

Clear visualization of complex subsurface conditions using 3D GPR reconstruction

Reduced risk during coring and anchor installation, protecting critical airport systems

Minimal disruption to ongoing airport operations

High confidence decision-making for renovation and equipment installation works

The result was a safer, more efficient project execution—where subsurface uncertainty was eliminated before construction began in one of Alberta’s most critical infrastructure facilities.