The Scantec Method: How GPR and X-Ray Deliver the Most Accurate Concrete Scanning Results

Why Concrete Scanning Matters

Cutting or drilling concrete without scanning can lead to serious consequences, including:

Striking post-tension cables

Damaging live electrical conduits

Compromising structural elements

Project delays and costly repairs

Safety hazards and liability exposure

Professional concrete scanning in Calgary helps mitigate these risks and provides confidence before intrusive work begins.

GPR and X-Ray Together Provide Superior Concrete Scanning Results

Concrete scanning is not about using a single tool or relying on branded terminology. At Scantec, it’s about data quality, validation, and risk reduction. When locating rebar, post-tension cables, conduits, embeds, and voids, the safest and most accurate approach is a layered methodology that combines advanced GPR acquisition techniques with targeted X-Ray radiography.

No single method performs perfectly under all conditions. Concrete thickness, reinforcement density, moisture content, and access constraints all influence results. That’s why Scantec applies multiple complementary techniques, each improving confidence before any cutting, coring, or drilling takes place.

Ground Penetrating Radar (GPR): Scantec’s Foundation Tool

Scantec uses professional-grade GPR systems from manufacturers such as GSSI, operated by experienced technicians trained in both radar physics and structural behavior.

GPR works by transmitting electromagnetic waves into concrete and recording reflections caused by changes in material properties. These reflections appear as hyperbolic signatures that indicate embedded objects or interfaces.

What GPR does best:

Rapid, non-destructive scanning of large areas

Detection of metallic and non-metallic targets

Mapping relative depth and spacing

Identifying congested or anomalous zones

However, GPR is an indirect method. Data quality and interpretation improve significantly when advanced acquisition techniques are applied.

How GPR works?

Ground Penetrating Radar (GPR) sends electromagnetic waves into concrete and records the signals that bounce back from changes in material or density. GPR is especially useful because:

✔️ It’s fast and non-invasive — you can scan large areas quickly.

✔️ It shows relative depths — deeper objects produce reflections later in the scan profile.

✔️ It can detect many types of targets — metal, voids, changes in concrete density, and more. It’s often the first step in scanning large slabs.

However, GPR has limitations:

⚠️ Signal clarity can vary based on concrete composition, moisture, and reinforcement density.

⚠️ Depth interpretation is relative — it doesn’t always show exact depths without velocity calibration.

⚠️ It provides indirect evidence — the reflections need interpretation by an experienced technician.

Several Advanced Techniques to improve GPR Used by Scantec

1. Normal and Cross-Polarized GPR Scanning

Scantec routinely uses both normal and cross-polarized antenna orientations where appropriate.

Normal polarization produces strong reflections from metallic targets such as rebar and post-tension cables and is ideal for general reinforcement mapping.

Cross-polarization is achieved by rotating the antenna 90°, changing the orientation of the electromagnetic field.

Why cross-polarization helps:

Reduces dominant reflections from dense rebar mats

Improves visibility of weaker targets such as non-metallic conduits or slab-bottom interfaces

Provides an alternate perspective for interpretation

Important clarification:

Cross-polarization is still GPR. Rotating the antenna improves interpretation but does not create a new technology and does not replace direct imaging methods such as X-Ray.

2. Double-Sided GPR Scanning (Top & Bottom of Slab)

At Scantec, double-sided scanning means scanning both the top and the underside of a concrete slab, not merely scanning in two directions on the same surface.

This technique is used when underside access is available and higher confidence is required.

Benefits of scanning both sides:

Shorter radar travel paths to targets

Improved resolution of top and bottom reinforcement

Reduced masking from dense reinforcement layers

More reliable depth and slab-thickness interpretation

Cross-validation of critical targets

Common applications:

Parking structures and suspended slabs

Bridge decks

Mechanical rooms

Office-to-residential conversions

High-risk coring or drilling locations

Double-sided scanning significantly improves GPR data quality but remains an indirect method that benefits from further validation on critical locations.

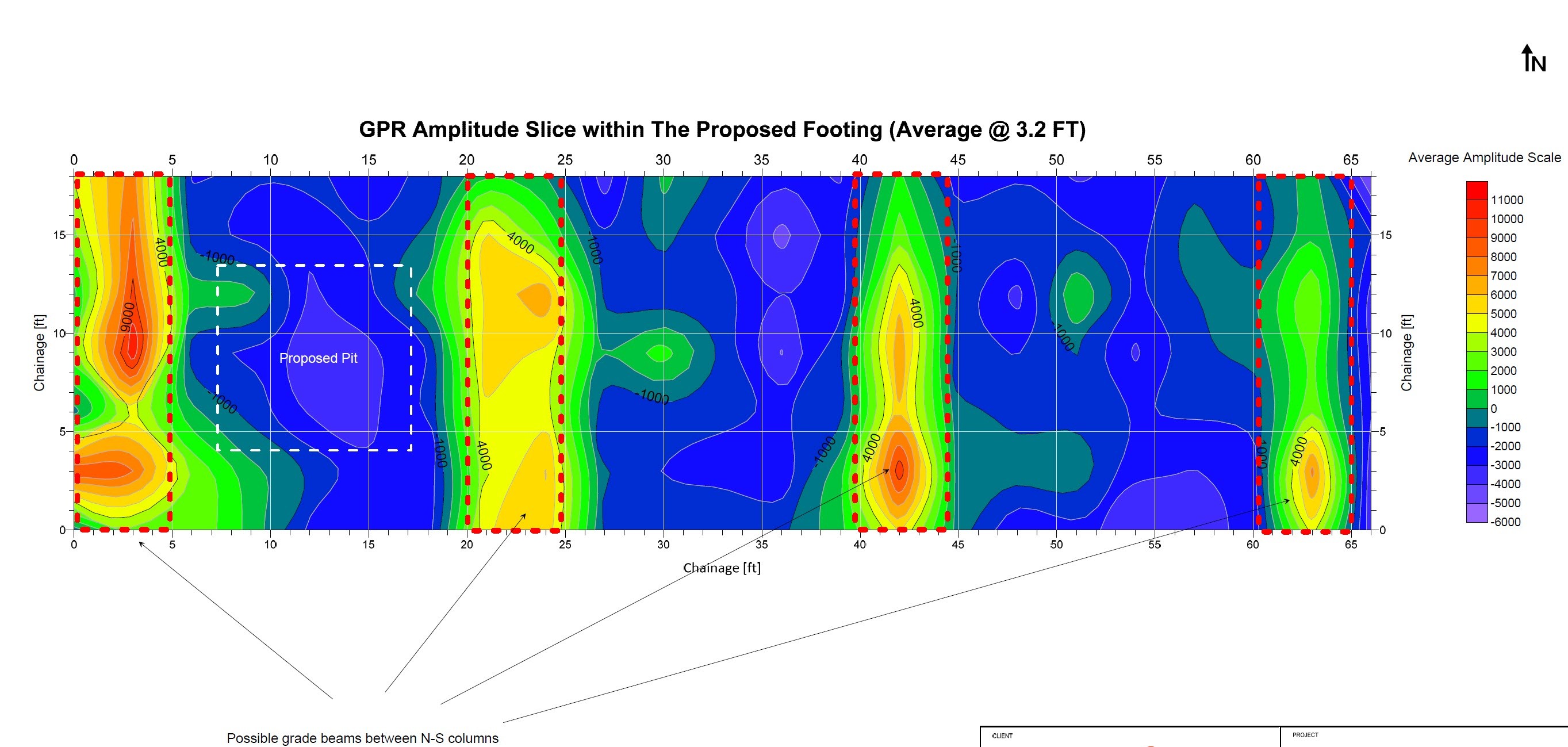

3. 3D GPR Modeling and Large-Area Quality Control

For large or complex projects, Scantec processes GPR data into 3D models and depth-slice visualizations.

3D modeling provides:

Horizontal depth slices at selected elevations

Visualization of reinforcement density patterns

Identification of anomalies not obvious in 2D profiles

Consistency checks across large scanned areas

This approach is particularly valuable for bridge decks, large floor plates, and infrastructure projects, where quality control across thousands of square metres is essential.

Understanding the Limits of Even Advanced GPR

Even with:

Cross-polarized scanning

Double-sided (top & bottom) acquisition

Dense line spacing

3D modeling and interpretation

GPR still relies on reflected electromagnetic energy, not direct imaging. In heavily congested slabs or high-risk penetrations, some uncertainty may remain.

That’s where X-Ray radiography becomes essential.

How X-Ray (Radiography) Works

X-Ray concrete scanning uses high-energy photons to penetrate concrete. A source and a detector are placed on opposite sides of a slab, and the resulting image shows the actual silhouettes of embedded objects.

Key strengths of X-Ray include:

📌 Direct imaging — you see the object’s outline, not just a reflection.

📌 Precise depth and position information — if you can place the detector correctly.

📌 High clarity for metal objects — rebar, cables, inserts, and post-tension tendons show up clearly.

But X-Ray is not perfect for every situation:

⚠️ Set-up and safety protocols are more complex than GPR.

⚠️ Coverage area per exposure is limited — you need multiple images for large areas.

⚠️ Radiation safety (ALARA protocols) must be strictly followed, requiring trained staff and shielding.

X-Ray Concrete Scanning: Scantec’s Validation Tool

X-Ray (radiography) uses high-energy photons to penetrate concrete and capture direct images of embedded objects on a digital detector.

What X-Ray adds:

Clear silhouettes of rebar, PT cables, conduits, and embeds

Precise positional and depth confirmation

Reduced interpretation ambiguity

Definitive validation for critical locations

Unlike GPR, X-Ray does not depend on polarization, antenna orientation, or signal interpretation — it directly images what is inside the slab.

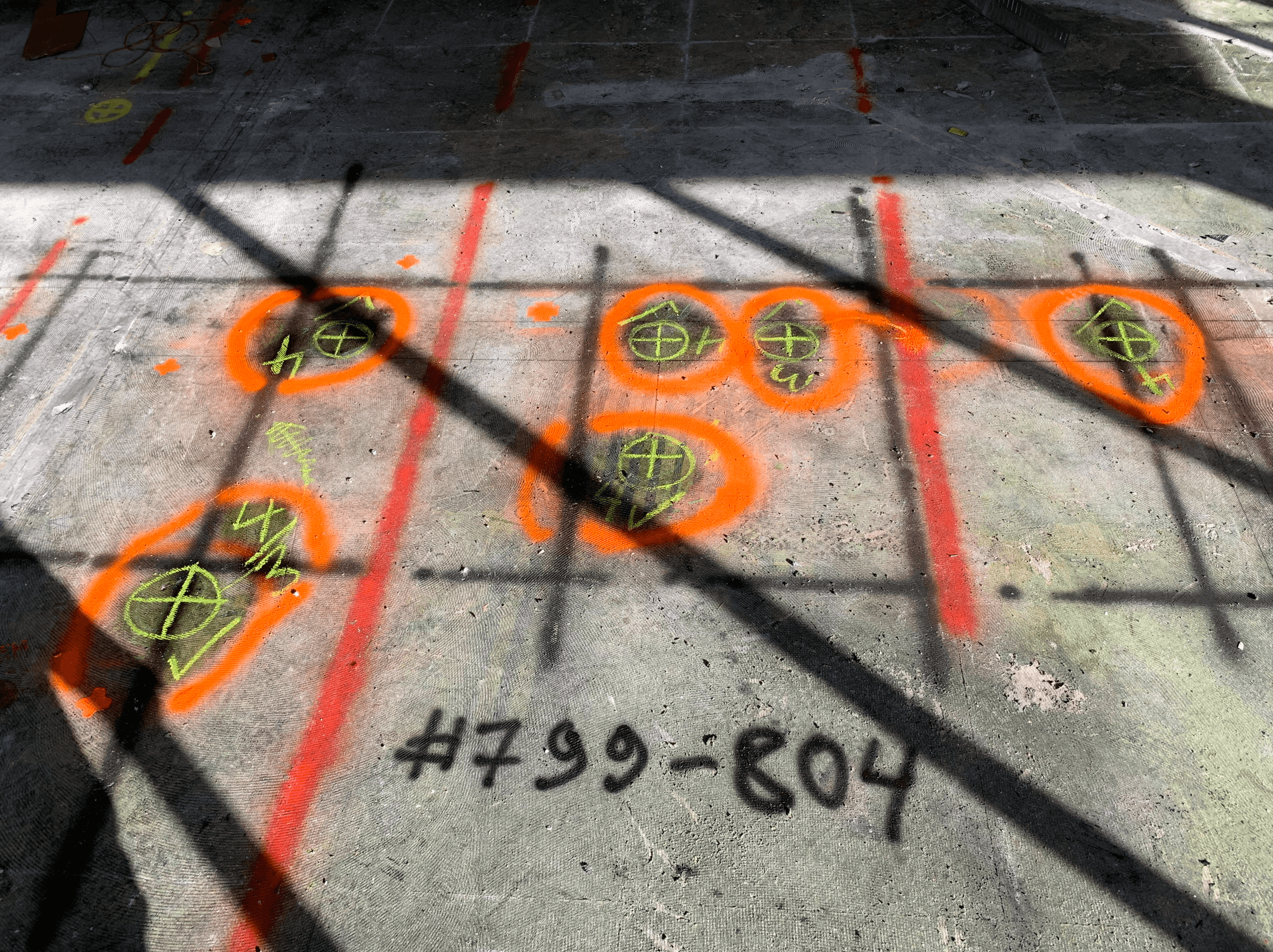

Scantec’s Integrated Concrete Scanning Workflow

Broad GPR scanning using normal and cross-polarized orientations

Double-sided scanning when underside access is available

3D modeling and quality control on large areas

Engineering interpretation and risk assessment

Targeted X-Ray radiography for definitive confirmation

This layered approach ensures decisions are made using cross-validated data, not assumptions.

Conclusion — Best Practice for Concrete Scanning

The Scantec Standard

The most reliable concrete scanning is achieved by combining:

Advanced GPR techniques (polarization, double-sided scanning, 3D modeling)

Sound engineering interpretation

Targeted X-Ray radiography when precision is critical

At Scantec, we use:

GPR to see broadly

Advanced techniques to see clearly

X-Ray to see definitively

That’s how we reduce risk, protect structures, and keep projects moving safely.

Need Concrete Scanning in Calgary, Edmonton or Vancouver Area?

Reduce risk before cutting, coring, or drilling.

Contact Scantec for professional concrete scanning in Calgary , Emonton, and Vancouver backed by experience, proven methods, and clear on-site marking.

Calgary: 587-917-1486

Edmonton: 780-246-2486

Vancouver: 236-979-2486

Email: info@scantecgpr.com